Special problems in oil and gas separation

1. separating foaming crude oil – when pressure is reduced on certain types of crude oil, tiny spheres (bubbles) of gas are encased in a thin film of oil when the gas comes out of solution. This may result in foam or forth, being dispersed in the oil and creates what is known as “foaming” oil. The major cause of foam in crude oil is the appearance of impurities, other than water, which are impractical to remove before the stream reaches the separator. Foam presents no problem within a separator if internal design assures adequate time for the foam to” break.” The main problems are:

· mechanical control of liquid level is aggravated, because any control device must deal with three liquid phase instead of two;

· foam can occupy much of the vessel space that would otherwise be available in the liquid collecting or gravity settling sections;

· sometimes it becomes impossible to remove separated gas or degassed oil from the vessel without entraining some of the foam material in either the liquid or gas outlets

2. paraffin – paraffin deposition in oil and gas separators reduces their efficiency and may render them inoperable by partially filling the vessel and\or blocking the mist extractor and fluid passages. Separator operation can be affected by an accumulation of paraffin. It may lead to plugging of some vessel internals. Where it is determined that paraffin is an actual or potential problem, the use of plate-type or centrifugal mist extractors should be considered. The bulk temperature of the liquid should always be kept above the cloud point of the crude oil.

3. sand, silt, mud and salt – sand can be very troublesome in separators by causing plugging of separator internals and accumulation at the bottom of the separator. Accumulation of sand can be alleviated by the use of sand jets and drains. Plugging of the separator internals is a problem that must be considered in the design of the separator.

Basic designs of separators

Two \ three-phase: a separator can be designed as two-or three-phase unit. A two-phase separator separates liquids from gases. A three-phase separator separates the liquid stream into its crude oil and water components.

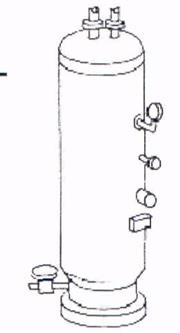

High and low pressure a separator can also be designed to process formation fluids under high and\or low pressures. They can be either vertical or horizontal separator.

|

|

|

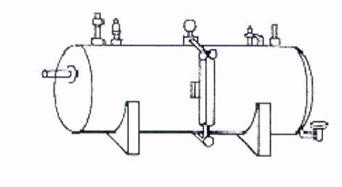

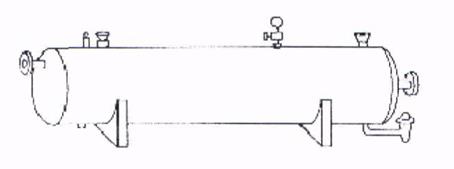

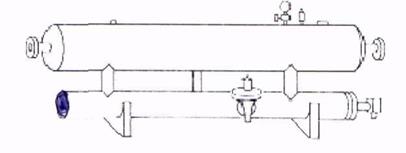

Single and dual – tube horizontal separators

In a single-tube horizontal separator, gas and oil move through a series of extractors to facilitate the separation, as gas moves along the upper section of the separator and oil flows along the bottom.

The upper tube of a double-tube separator is similar to that of a single-tube except the oil falls to the lower tube, where it is moved to the storage tanks.

| anticipated flow rate | ожидаемый расход |

| baffle arrangement | каплеотбойное устройство |

| bulk temperature | объемная температура, средняя температура |

| cloud point | температура начала выпадения парафинов |

| deflector cone | дефлекторный конус |

| drain | спускное отверстие; слив |

| dual-tube separator | двухемкостной сепаратор |

| foamy crude | пенистая нефть |

| gas outlet | выход газа |

| gas-liquid interface | поверхность раздела газ-жидкость |

| gas-oil ratio (GOR) | газовый фактор |

| high-pressure separator | сепаратор высокого давления |

| impurities | примеси |

| inlet diverter | входной распределитель потока |

| mechanical level control | механическая регулировка уровня |

| mist extractor | туманоуловитель, каплеотбойник |

| primary treatment | первичная обработка |

| sand jet | струйный вымыв песка |

| settling section | осадительная секция (сепаратор) |

| specific gravity | удельная плотность |

| surge | пульсация |

| swirl chamber | вихрекамера |

| swirling motion | вихревое движение |

| three-phase separator | трехфазный сепаратор |

| two-phase separator | двухфазный сепаратор |

| vessel internals | внутрикорпусные устройства, ВКУ |

|

|

|

Дата добавления: 2019-01-14; просмотров: 101; Мы поможем в написании вашей работы! |

Мы поможем в написании ваших работ!