Strength properties of the rubber

Activation characteristics of rubber (  ) are determined from rubber dumbbells tension experiments. The experimental procedure for obtaining data Fig. 3.7 is simple: the dumbbell is loaded with a constant stress

) are determined from rubber dumbbells tension experiments. The experimental procedure for obtaining data Fig. 3.7 is simple: the dumbbell is loaded with a constant stress  , for compensation of creep Liderman device is used. The time before breakage of dumbbells is recorded.

, for compensation of creep Liderman device is used. The time before breakage of dumbbells is recorded.

The statistical processing of the results was carried out: for each experimental point when  not less 15 of dumbbells were fractured the dispersion of time before fracture did not exceed 0.5 power of decimal logarithm, the greatest deviation interpolation results from mean elective did not exceed 0.2 power (visual explanation in Fig. 3.7). The experiment was carried out for three values of temperatures: T = 293 K = 20 °С, T = 333 K = 60 °С, T = 373 K = 100 °С, corresponds to three straight line in Fig. 3.7.

not less 15 of dumbbells were fractured the dispersion of time before fracture did not exceed 0.5 power of decimal logarithm, the greatest deviation interpolation results from mean elective did not exceed 0.2 power (visual explanation in Fig. 3.7). The experiment was carried out for three values of temperatures: T = 293 K = 20 °С, T = 333 K = 60 °С, T = 373 K = 100 °С, corresponds to three straight line in Fig. 3.7.

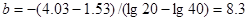

The static strength exponent b is determined from results of experiments for the time before fracture  of samples when they are loaded with different forces (different tensile stresses

of samples when they are loaded with different forces (different tensile stresses  ) at constant temperature of surroundings

) at constant temperature of surroundings

.

.

From straight line corresponding to temperature T = 293 K :  .

.

The activation energy of  is determined from the results of samples at fracture when they are loaded with same forces at different temperatures

is determined from the results of samples at fracture when they are loaded with same forces at different temperatures

.

.

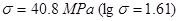

For example, at burst stress  when temperature T = 333 K

when temperature T = 333 K  , while when T = 293 K

, while when T = 293 K  . We will obtain activation energy

. We will obtain activation energy

.

.

The parameter  is determined from the results of samples fracture at fixed temperature and tensile stress. Knowing fracture time, the formula for determining the constants is

is determined from the results of samples fracture at fixed temperature and tensile stress. Knowing fracture time, the formula for determining the constants is

At temperature T = 293 K и and tensile stress  the lifetime equals to

the lifetime equals to  . Thus,

. Thus,

.

.

It is already known, that parameter a is determined from contraction of cylindrical samples test. From experimental results at tensile stress  , time before fracture when temperature T = 293 K from formula (3.2) lifetime equals to

, time before fracture when temperature T = 293 K from formula (3.2) lifetime equals to

.

.

The value 0.952 is the lifetime of the dumbbells without external pressure. The value 1.678 (is the value of longevity) with consideration of hydrostatic pressure inside the cylinder. On the graph in Fig. 3.7, the relationship of cylinder lifetime with tensile stress  is shown. Consideration of the parameter a, that the relationship ceases to be linear.

is shown. Consideration of the parameter a, that the relationship ceases to be linear.

Fig. 3.7

Conclusions (brief basis)

The activation characteristics (strength properties) of the elastomer E50189 are: σeng = 19 MPa, ε f = 1.93, σf = 55.6 MPa at 20C; Uo = 80.0 kJ/mol, b = 8.3, lgc = 0.56.

|

|

|

These values and relation (3.2) were used for life estimation of the seals.

The procedure how were defined experimentally these values was shown.

References

1. NORSOK Standard M-710. Qualification of non-metallic sealing materials and manufacturers.

2. International standard ISO 11346. Rubber, vulcanized or thermoplastic – Estimation of life-time and maximum temperature of use from an Arrhenius plot.

3. Lazarev S. et al. The prediction of sealing lifetime of elastomer seals. Report for FMC Wellhead Equipment Division, Houston, 1996.

4. Underwriters laboratories Inc. UL 746B Standard for polymeric material – Long term property evaluations, 2nd ed., 1979.

5. Extrapolation of accelerated aging data – Arrhenius or Erroneous ? Kenneth T. Gillen et al. Polymer science. Vol. 5, N 8, 1997.

6. Vicic J. Failure life determination of oilfield elastomer seals in sour gas/dimethyl disulfide environments. Corrosion ’89. Paper 212. New Orleans.

7. Vicic J. et al. A review of polymer life estimation using variable temperature / stress acceleration methods. Elastomer service Life Prediction Symposium ’97. Akron.

8. www.mscsoftware.com

How and why do structures fail?

Note: the copies of all papers can be sent on request.

Дата добавления: 2019-09-13; просмотров: 154; Мы поможем в написании вашей работы! |

Мы поможем в написании ваших работ!