Calculationofexpansionparameters

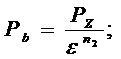

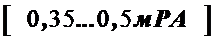

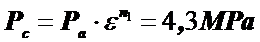

1) Expansionendpressure:

,

,

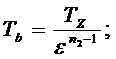

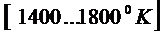

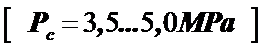

2) Expansiontemperature:

,

,

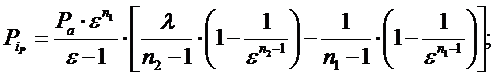

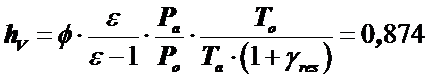

3) Mean calculated pressure of the cycle:

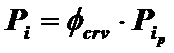

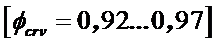

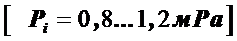

The actual average indicated pressure, taking into account the curvature factor of the indicated diagram.

;

;

.

.

KeyPerformanceIndicators

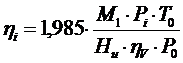

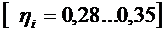

1) Indicatedefficiency:  ;

;  .

.

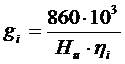

2) Fuel consumption per one indicator kW. hour:

;

;  .

.

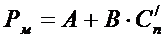

3) The proportion of indicated pressure used for friction and drive of auxiliary units (pumps, generator, etc.):

,

,

whereАиВ – coefficients that depend on the ratio of the stroke of the piston to the diameter of the cylinder (S / D):

atS / D ≤ 1 А = 0,04; В = 0,0135;

atS / D> 1 А = 0,05; В = 0,0155;

- average piston speed, м/с ,

- average piston speed, м/с ,

[Сп = 9…12м/с, for high-speed motors with

n > 4000min–1we takeСп ≥ 12 м/с].

Mean effective cycle pressure

Ре = Рi – Рм; [Ре= 0,6…0,95 МPа.];

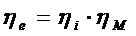

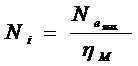

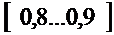

4) Mechanicalefficiency:  ; [

; [  = 0,75…0,82].

= 0,75…0,82].

5) Effectiveefficiency:  ; [

; [  = 0,23…0,29].

= 0,23…0,29].

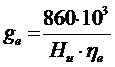

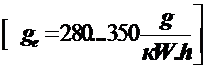

6) Specificeffectivefuelconsumption:

;

;  .

.

Basic dimensions of the cylinder

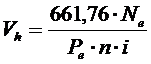

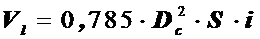

1) Working volume of one cylinder

.

.

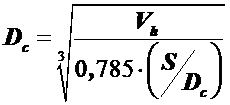

2) Diameter of the inner surface of the cylinder:

.

.

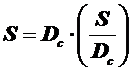

3) Pistonstroke

.

.

Finally, for the convenience we round up values to integers.

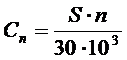

4) Speed (average) of the piston:  .

.

Speed  should not differ from the chosen one by more than 5...10 %, otherwise, it is necessary to recalculate the effective indicators.

should not differ from the chosen one by more than 5...10 %, otherwise, it is necessary to recalculate the effective indicators.

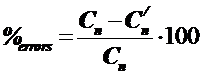

< (5…10 %).

< (5…10 %).

5) Enginedisplacement  .

.

6) Effectivepower  .

.

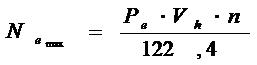

7) Indicatedpower  .

.

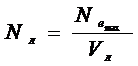

8) Volumetricpower  .

.

9) Effective torqueМе = 5266·  , N·m.

, N·m.

10 ) Indicatedtorque  .

.

An example of thermal calculation of a diesel engine

engine type - diesel;

number of cylinders – 8 (row orV – figurative);

Nominal power:  = 110 кW;

= 110 кW;

Engine crankshaft speed:п = 3000min-1;

Compression ratio:ε = 16,5;

Coefficient of excess air: = 1,35;

Piston stroke to cylinder diameter ratio:S / D = 0,9;

type of mixture - with direct injection of fuel;

fuel - diesel, compositionС = 0,87; Н = 0,126; О2 = 0,004;

lowest calorific valueНи = 10000 kcal / kg.

Additionaldata selection

1) Ambientpressure:Р0 = 0,1 МPа;

2) AmbienttemperatureТ0 = 3000 К;

3) Residual gas pressureРr = 0,12 МPа;

4) Residual gas temperatureТr = 8500К

[Тr=700…9000 К];

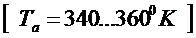

5) The air temperature at the time it enters the cylinder

|

|

|

= Т0 +ΔТ = 300 + 30 = 3300 К;

= Т0 +ΔТ = 300 + 30 = 3300 К;

[ΔТ = 20…400].

6) The polytrophic exponent n1 and the polytrophic exponents n2 are taken according to the speed regime:

[п1 = 1,28…1,4]; п1 = 1,38;

[п2 = 1,18…1,28]; п2 = 1,23.

7) Coefficient of active heat release

ξ = 0,78; [ξ = 0,7…0,85].

6) Gas pressure in the cylinder at the end of the intake

Ра = 0,089 МPа, [Ра =( 0,85…0,95) Ро].

For high-speed diesels take the lower limit.

Determination of intake properties

1) Coefficientofresidualgases

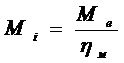

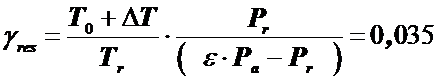

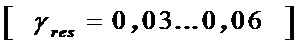

,

,

.

.

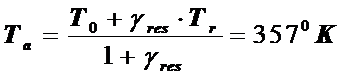

2) Determination of the temperature of the gases in the cylinder at the end of the intake.

,

,

.

.

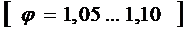

3) Fillingratio

,

,

where  - charge factor,

- charge factor,  .

.

Determiningof the compression parameters

The pressure of gases in the cylinder at the end of compression

,

,  .

.

The temperature of the gases in the cylinder at the end of compression

,

,  .

.

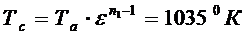

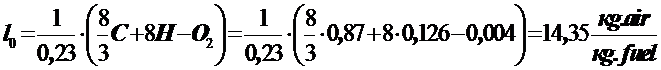

Workingheatcalculation

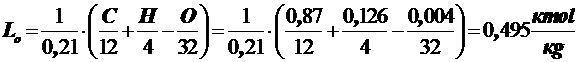

Theoretically necessary amount of air for complete combustion of 1 kg of fuel

,

,

orin moles  .

.

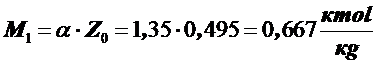

1) The total amount of air

,

,

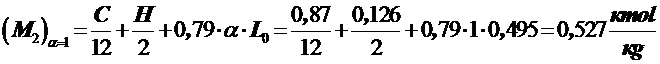

The total amount of combustion products M2 will consist of combustion products at α = 1 and excess air which is not participating in combustion  .

.

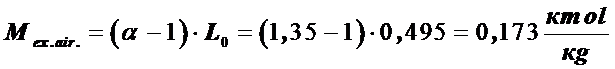

Excess amount of fresh air

,

,

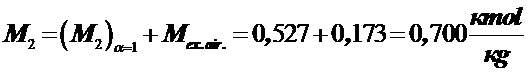

Total amount of combustion products

.

.

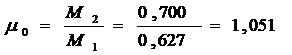

Chemical coefficient of molecular change

.

.

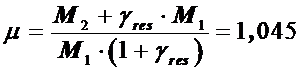

The actual coefficient of molecular change

.

.

Дата добавления: 2018-02-28; просмотров: 271; Мы поможем в написании вашей работы! |

Мы поможем в написании ваших работ!