The control card for quantitative data

Standard values aren’t set

Data. Results of measurements are given in table 6. Four measurements became, all 20 selections are taken.Averages and scope of subgroups are also given in table 6.Maximum permissible values are established:

Rmaх=1,000

Rmin=0,900

n=4

k=20

The purpose – definition of indicators of process and management of him on control and dispersionso that he conformed to the established requirements.

k – number of subgroups

k – number of subgroups

CL – center line

CL – center line

UCL – top control line

LCL – lower control line

n – volume of subgroup, number of selectiveobservations in subgroup

R – scope of subgroup

X – the measured characteristic of quality

–average value for subgroup

–average value for subgroup

– average of average values of subgroups

– average of average values of subgroups

–average value R for all subgroups

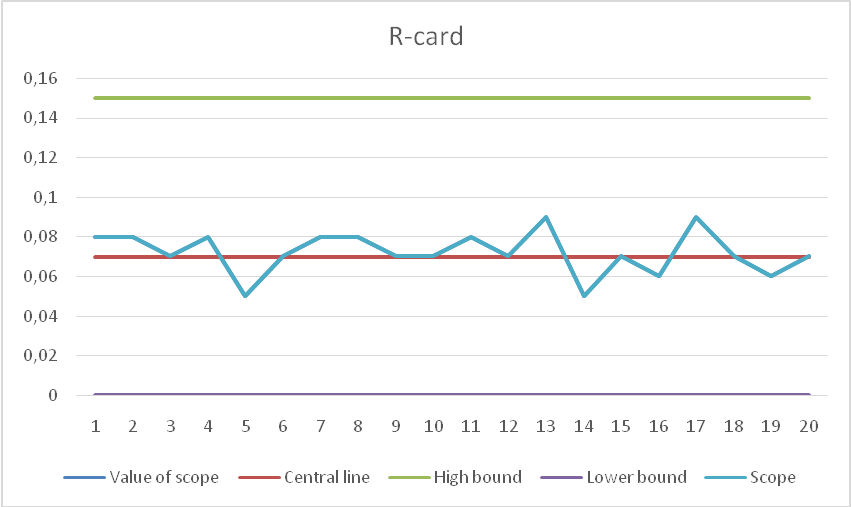

First step: creation of R-cards and definition of a condition of process.

R-CARD

From table 7 at n=4 for the R-card

D4=2,282 D3=0, if n<7 and if n<7 LCL absent

= 0,15UCL=0,15

= 0,15UCL=0,15

LCL= 0,000

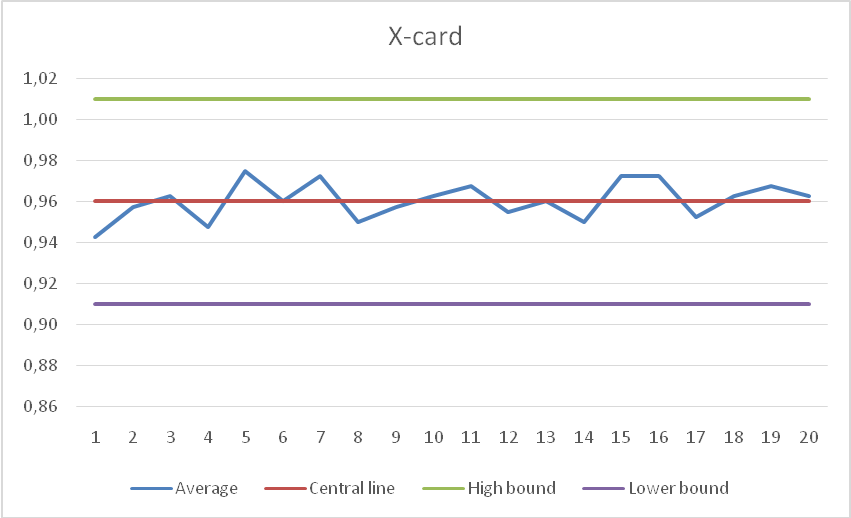

CL=0,96

= 0

CARD OF SCOPE

| Number of subgroup | Value of scope | Central line | High bound | Lower bound | Scope |

| 1 | 0,08 | 0,07 | 0,15 | 0,00 | 0,08 |

| 2 | 0,08 | 0,07 | 0,15 | 0,00 | 0,08 |

| 3 | 0,07 | 0,07 | 0,15 | 0,00 | 0,07 |

| 4 | 0,08 | 0,07 | 0,15 | 0,00 | 0,08 |

| 5 | 0,05 | 0,07 | 0,15 | 0,00 | 0,05 |

| 6 | 0,07 | 0,07 | 0,15 | 0,00 | 0,07 |

| 7 | 0,08 | 0,07 | 0,15 | 0,00 | 0,08 |

| 8 | 0,08 | 0,07 | 0,15 | 0,00 | 0,08 |

| 9 | 0,07 | 0,07 | 0,15 | 0,00 | 0,07 |

| 10 | 0,07 | 0,07 | 0,15 | 0,00 | 0,07 |

| 11 | 0,08 | 0,07 | 0,15 | 0,00 | 0,08 |

| 12 | 0,07 | 0,07 | 0,15 | 0,00 | 0,07 |

| 13 | 0,09 | 0,07 | 0,15 | 0,00 | 0,09 |

| 14 | 0,05 | 0,07 | 0,15 | 0,00 | 0,05 |

| 15 | 0,07 | 0,07 | 0,15 | 0,00 | 0,07 |

| 16 | 0,06 | 0,07 | 0,15 | 0,00 | 0,06 |

| 17 | 0,09 | 0,07 | 0,15 | 0,00 | 0,09 |

| 18 | 0,07 | 0,07 | 0,15 | 0,00 | 0,07 |

| 19 | 0,06 | 0,07 | 0,15 | 0,00 | 0,06 |

| 20 | 0,07 | 0,07 | 0,15 | 0,00 | 0,07 |

To construct the chart – it is necessary "to take the block" columns A and B, to press in the menu charts and to construct curves. To build the central line both the top and lower borders – it is necessary "to take the block" B, C, D, E and to construct these straight lines on the chart.

|

|

|

CARD OF THE AVERAGE

| Number of subgroup | Average | Central line | High bound | Lower bound |

| 1 | 0,91 | 0,95 | 0,92 | 0,99 |

| 2 | 0,98 | 0,93 | 1 | 0,92 |

| 3 | 1 | 0,95 | 0,93 | 0,97 |

| 4 | 0,99 | 0,92 | 0,91 | 0,97 |

| 5 | 0,97 | 1 | 0,98 | 0,95 |

| 6 | 0,97 | 0,92 | 0,99 | 0,96 |

| 7 | 0,98 | 0,99 | 1 | 0,92 |

| 8 | 1 | 0,92 | 0,95 | 0,93 |

| 9 | 0,98 | 0,94 | 0,92 | 0,99 |

| 10 | 0,93 | 0,96 | 1 | 0,96 |

| 11 | 1 | 0,92 | 0,99 | 0,96 |

| 12 | 0,94 | 1 | 0,93 | 0,95 |

| 13 | 0,98 | 0,91 | 1 | 0,95 |

| 14 | 0,97 | 0,95 | 0,92 | 0,96 |

| 15 | 0,99 | 0,97 | 0,93 | 1 |

| 16 | 0,94 | 1 | 0,96 | 0,99 |

| 17 | 1 | 0,93 | 0,97 | 0,91 |

| 18 | 0,93 | 0,97 | 1 | 0,95 |

| 19 | 0,96 | 1 | 0,94 | 0,97 |

| 20 | 0,95 | 0,97 | 0,93 | 1 |

Test products

Test is a technical operation which consists in definition of one or several characteristics of production according to the established procedure by the adopted rules. Also test is called experimental determination of quantitative and qualitative properties of a subject to tests at his direct functioning or when modeling an object and (or) impacts on him. Such definition is carried out by carrying out measurements, however in general test of production doesn't come down to simple measurements of its properties.

Subject to test is production or processes (technology) of her production. At the same time depending on a type of production and test objectives both the single product, and party can be an object. Tests of production carry out in process, or upon termination of her production, and also at her operation.

The concept "test" assumes some impacts on the tested object which it has to maintain or not maintain. Therefore it is important when carrying out any tests a task of the modelled service conditions, real or close to them.

|

|

|

Understand set of the influencing factors and modes of functioning of an object at tests as test conditions, at the same time the major influencing factors are mechanical, climatic, biological or electromagnetic. Not concrete results of measurements are result of tests, but answers of type "is suitable", "isn't suitable", "corresponds", "doesn't correspond". Thus, the test objective consists in assessment of true value of the determined parameter in the set nominal test conditions.

Normative documents on tests of concrete objects establish an order of carrying out tests which have to be carried out according to developed by the program and a technique.

The program of tests – the obligatory document establishing an object and test objectives: types, the sequence and volume of the made experiments; order, conditions, place and terms of carrying out tests; providing and reporting; responsibility for providing and carrying out tests.

Technique of tests – the obligatory document including a method, means and test conditions, sampling, algorithms of performance of operations on definition of characteristics of properties of an object, a form of data presentation and estimation of accuracy and reliability of results, requirements of safety measures and environmental protection.

Test method – the established technical rules of carrying out test.

The test report – the document containing results of tests and the other information relating to tests.

At test of kefir the following methods are used:

Determination of temperature of a product at release from the enterprise and the net weight of a product - in accordance with GOST 3622 and according to the normative documents existing in the territory of the states which have adopted the standard.

Definition of a mass fraction of fat - in accordance with GOST 5867 and to the normative documents existing in the territory of the states which have adopted the standard.

Determination of acidity - in accordance with GOST 3624 and to the normative documents existing in the territory of the states which have adopted the standard.

|

|

|

Definition of yeast, pleseney-in accordance with GOST 10444.12.Determination of temperature of a product at release from the enterprise and the net weight of a product - in accordance with GOST 3622 and according to the normative documents existing in the territory of the states which have adopted the standard.

General rules of sampling

Sampling is made after check of a condition of a container and establishment of uniformity of party. In case of mixture of parties production is sorted on uniform parties.

Examine all party completely and note shortcomings of a condition of a container (malfunction of a container, lack of seals, pollution, existence of a mold, leak, lack of marking or not clear marking and so forth).

From the products delivered in the damaged container, tests select separately.

Tests select from the products packed only into a serviceable container.

Sampling for the microbiological analysis of milk and dairy products is made in accordance with GOST by 9225-84.

Rules of sampling and the size of average test for a laboratory research depend on a type of a product and character of a research.

By agreement of the parties the quantity of controlled units of packing and the selected tests can be increased.

Counting of controlled units of packing is made in a selective order on standards of the present standard.

Before opening of controlled places of a cover of flasks, tubs, barrels and external walls of a container clean, wash out or wipe.

Organoleptic indicators of milk and dairy products estimate on each controlled unit of packing separatelySampling of separate products and preparation them to test.

Milk and milk drink

Before sampling of milk and milk drink from the molokokhranilnykh of capacities (a bathtub, the tank) and tanker trucks milk and milk drink mix in the mechanical way within 3-4 min., without allowing strong foaming and transfusion too much and trying to obtain its total homogeneity. Before sampling of milk and milk drink from flasks milk and milk drink mix a verticil, moving it 8-10 times up and down. The verticil has to have the handle of such length that at immersion of a verticil to the bottom a part of the handle remained not shipped.

|

|

|

From milk and the milk drink produced in automobile tanks, tests select a mug or a metal tube from each section of the tank separately in the clean and rinsed by the studied milk and milk drink vessel.

From milk and the milk drink produced in flasks as controlled places select 5% of flasks of their general quantity.

After hashing of milk and milk drink in flasks make sampling by a metal tube, immersing it to the bottom flasks with such speed that milk and milk drink came to a tube along with her immersion. Tests of milk and milk drink transfer from each controlled place to the clean and rinsed by the studied milk and milk drink vessel and from there after hashing allocate an average sample of 500 cm.

In order to avoid premature pouring out from a tube of a part of the selected portion of milk and milk drink the tube with milk and milk drink should be held vertically.

From milk and the milk drink packaged in bottles or packages as average test select the following quantity of units of packaging:

1-2 - up to 100 boxes;

2-3 - from 100 to 200 boxes;

3-4 - from 200 to 500 boxes;

4-5-ot 500 do 1000 ofboxes.

Milk and milk drink of each selected unit of packaging investigate separately.

The average test of milk and milk drink intended for definition of physical and chemical and organoleptic indicators after hashing bring (20±2) °C to temperature.

Hashing of milk and milk drink is made by a perevertyvaniye of a bottle or transfusion of contents of a bottle in other dry ware and back not less than two times. Average test of milk and milk drink remains until the end of test.

In the presence of the defended grease layer (cream) test of milk and milk drink is heated in a water bath to 30-40 °C, mixed and cool (20±2) °C up to the temperature.

Fermented milk products

Sampling for definition of physical and chemical indicators of the lactic products packaged in bottles or packages and also in other small packing, is made as it is specified in item 3.1.6.

Tests of fermented milk products mix and bring (20±2) °C to temperature. Hashing of fermented baked milk, curdled milk, acidophilic and other types of paste, yogurt of 6% fat content, varenets make the pallet, and acidophilus milk, acidophilous milk, kefir, koumiss and other dairy drinks - by a repeated perevertyvaniye of a bottle with contents before receiving a product of uniform consistence.

Kefir and koumiss pour out in a chemical glass, put it for 10 min. in a water bath with the temperature of 30-35 °C, then contents mix for removal of carbonic acid and cool (20±2) °C up to the temperature.

After opening and measurement of temperature sour cream is mixed a verticil. Depending on consistence of sour cream average tests of sour cream select a scoop, the probe or a tube, immersing them to the bottom a container, then transfer tests to one clean dry ware for physical and chemical researches from where after hashing allocate an average sample with a lump not less than 100 g.

Definition of a mass fraction of fat - in accordance with GOST 5867 and to the normative documents existing in the territory of the states which have adopted the standard.

Sampling methods. Sampling of milk and dairy products and preparation them to analyses - in accordance with GOST 13928, GOST 3622 and GOST 26809

Acid method. The method is based on release of fat from milk, milk drink, dairy and milk-containing products, fermented milk products, cheese and cheese products, oil and oil paste, creamy and vegetable spread and creamy and vegetable melted mix, ice cream under the influence of concentrated by a chamois of acid and izoamilovy alcohol with the subsequent centrifugation and measurement of volume of the emitted fat in the graduated part of a zhiromer.

Equipment, materials and reactants.

- Zhiromera (butyrometers) glass executions 1-6, 1-7, 1-40, 2-0,5, 2-1,0 in accordance with GOST 23094ili TU 25-2024.019.

- Traffic jams rubber for zhiromer on TU 38-105-1058.

- Pipettes 2-1-5, 3-1-5, 6-1-10, 7-1-10 and 2-1-10, 77 in accordance with GOST 29169

- Rubber pear.

- Devices (batchers) for measuring off of izoamilovy alcohol and sulfuric acid capacity, respectively, 1 and 10 cm in accordance with GOST 6859.

The centrifuge for measurement of a mass fraction of fat of milk and dairy products according to the specifications and technical documentation with a frequency of rotation not less than 1000 with and no more than 1100 pages.

- Baths are the water, providing maintenance temperature of (65±2) °C and (73±3) °C.

- The device heating for a water bath.

- A support for zhiromer.

- Thermometers mercury glass with a range of measurement from 0 to 100 °C, with the price of division of 0,5 and 1,0 °C in accordance with GOST 28498.

- Scales laboratory the 4th class of accuracy with the greatest limit of weighing of 200 g in accordance with GOST 24104.

- Cylinder 1-50, 1-100 in accordance with GOST 1770.

- The areometer of general purpose with a range of measurement from 700 to 2000 kg/m in accordance with GOST 18481.

- Hourglasses for 5 min. or a stop watch according to the specifications and technical documentation.

- Acid sulfuric in accordance with GOST 4204 or acid sulfuric technical in accordance with GOST 2184 (kuporosny oil of contact and concentration systems).

- Alcohol izoamilovy in accordance with GOST 5830 or alcohol izoamilovy technical, grade And.

- The water distilled in accordance with GOST 6709.

- use of other measuring instruments with metrological characteristics Is allowed and it isn't worse than the equipment with technical characteristics and also reactants on quality isn't lower than above-stated.

Carrying out measurements.

Milk (crude, pasteurized different types, except fat-free, sterilized, for baby food and milk drink)

In two dairy zhiromer (types 1-6 or 1-7), trying not to moisten a throat, pour the batcher 10 cm of sulfuric acid (density from 1810 to 1820 kg/m) and it is careful that liquids didn't mix up, add the pipette 10,77 cm of milk, having put a pipette tip to a throat of a zhiromer at an angle.

Milk level in the pipette is installed on the lower point of a meniscus.

Milk from the pipette has to follow slowly. After depletion the pipette is taken away from a mouth of a zhiromer not earlier than through 3 pages. Blowing of milk from the pipette isn't allowed. The batcher add 1 cm of izoamilovy alcohol in zhiromer.

Mix level in a zhiromer is established 1-2 mm below by the bases of a mouth of a zhiromer for what it is allowed to add several drops of the distilled water.

It is recommended for increase in accuracy of measurements, especially for milk of low density, to apply weighing at a test dosage. In this case at first weigh 11,00 g of milk with counting to 0,005 g, then flow sulfuric acid and izoamilovy alcohol.

Zhiromera close dry traffic jams, entering them a little more than half into a mouth of zhiromer. Zhiromera stir up before full dissolution of albumens, overturning not less than 5 times so that liquids in them have completely mixed up.

It is recommended to apply for ensuring carrying out measurements chalk on a surface of traffic jams for packing of zhiromer.

Zhiromer by a stopper down for 5 min. in a water bath at a temperature establish (65±2) °C.

Having taken out from a bath, zhiromer insert into glasses of the centrifuge the graduated part to the center. Zhiromera symmetrize, one against another. At odd number of zhiromer place in the centrifuge the zhiromer filled with water instead of milk, sulfuric acid and izoamilovy alcohol in the same ratio as for the analysis.

Zhiromera centrifuge 5 min. Each zhiromer take out from the centrifuge and the movement of a rubber stopper regulate a fat column so that he was in the graduated part of a zhiromer.

Zhiromera immerse traffic jams down for 5 min. in a water bath at a temperature (65±2) °C, at the same time water level in a bath has to be slightly higher than the level of fat in a zhiromer.

Zhiromera take out on one of a water bath and quickly make fat counting. When counting a zhiromer hold vertically, the border of fat has to be at the level of eyes. Establish by the movement of a stopper the lower bound of a column of fat on zero or whole division of a scale of a zhiromer. From him count number of divisions to the lower point of a meniscus of a column of fat to within the smallest division of a scale of a zhiromer.

The limit of the section of fat and acid has to be cutting, and a fat column transparent. In the presence of "ring" (stopper) of brownish or dark yellow color, various impurity in a column of fat or the indistinct lower bound measurement is taken repeatedly.

In the analysis of the homogenized or restored milk definition in him a mass fraction of fat is carried out according to the above described requirements, but carry out triple centrifugation and heating between each centrifugation in a water bath at a temperature (65±2) °C within 5 min.

When using the centrifuge with heating of zhiromer carrying out one centrifugation within 15 min. with the subsequent endurance in a water bath at a temperature (65±2) °C within 5 min. is allowed.

Fermented milk products (kefir, curdled milk, fermented baked milk, acidophilus milk, sour cream, cottage cheese, cottage cheese products, etc., including fermented milk products for baby food), cream, ice cream.

Definition of fat is carried out according to subitem 2.2.1.1-2.2.1.7, requirements specified in tab. 1 and the following additional conditions:

- the sequence of operations when filling a zhiromer - a product otveshivaniye in a zhiromer with counting to 0,005 g, water addition (if necessary), sulfuric acid and izoamilovy alcohol;

sulfuric acid in a zhiromer with water is added carefully, having slightly inclined a zhiromer;

- when determining fat in cream, sour cream, cottage cheese, cottage cheese products and ice cream warming up of zhiromer with the studied mix before centrifugation is carried out in a water bath at frequent stirring to full dissolution of protein;

- when determining fat in cream, sour cream and milk ice cream mix level in a zhiromer is established 4-5 mm below by the bases of a mouth of a zhiromer, when determining fat in creamy ice cream and ice cream - on 6-10 mm.

Processing of results. Take arithmetic-mean value of results of two parallel observations between which divergence (convergence) doesn't exceed values for result of measurements.

Показанияжиромераприизмеренияхвмолоке, вт.ч. нежирном; кисломолочныхпродуктах, вт.ч. сметане, твороге; сливках (смассовойдолейжиранеболее 40%), сливочноммороженом, пломбире, пахтеисывороткесоответствуютмассовойдолежиравэтихпродуктахвпроцентах.

Mass fraction of fat X, %, in milk ice cream and cheese calculate on a formula:

(8)

(8)

in cream with a mass fraction of fat more than 40% and in oil with fillers on a formula:

(9)

(9)

Where, P - result of measurements on item 2.3.1, %;

M-mass of a hinge plate;

11 and 5 - the mass of hinge plates of products which uses for graduation of zhiromer.

The mass fraction of fat in cheese and a cheese product in terms of X_1 solid, %, is calculated on a formula:

(10)

(10)

Determination of acidity - in accordance with GOST 3624 and to the normative documents existing in the territory of the states which have adopted the standard.

Sampling methods

Methods of sampling of milk and dairy and milk-containing products and preparation them to the analysis in accordance with GOST 13928 and GOST 26809.

Electrometric method.

The method is applied at emergence of disagreements.

The method is based on neutralization of the acids which are contained in a product, sodium hydroxide solution to in advance preset value рН =8,9 by means of the block of automatic titration and indication of a point of equivalence by means of the electrometric analyzer.

Equipment, materials and reactants

- The analyzer electrometric with a range of measurement of 4-10 units рН with the price of division of a scale of 0,05 units рН.

- The block of automatic titration, no more than 0,05 cm are hardware the compatible to an electrometric titrator and having solution batcher (burette) with a capacity not less than 5 cm with the division price.

- Scales laboratory the 4th class of accuracy with the greatest limit of weighing of 200 g in accordance with GOST 24104

- Glasses of B-1-50 of the CU, B-2-50 of the CU, B-1-100 of the CU, B-2-100 of the CU in accordance with GOST 25336.

- Flasks 1-1000-2, 2-1000-2 in accordance with GOST 1770.

- Pipettes 2-2-10, 2-2-20 in accordance with GOST 29169.

- Cylinders 1-50-1, 1-50-2, 3-50-1, 3-50-2 in accordance with GOST 1770.

- A mortar porcelain with a pestle in accordance with GOST 9147.

- Sodium a hydroxide, the standard caption on TU 6-09-2540, solution with molar concentration of 0,1 mol/dm.

- The water distilled in accordance with GOST 6709.

Use of other gages with metrological characteristics is allowed and it isn't worse than the equipment with technical characteristics and also reactants on quality isn't lower than above-stated.

Preparation for test

Preparation of devices

Connect the block of automatic titration to the analyzer according to the instruction attached to the block. Then connect the block and the analyzer to network and warm up them within 10 min.

Fill the batcher of the block of automatic titration with sodium hydroxide solution.

According to the instruction attached to the electrometric analyzer adjust it on such range of measurement рН which would include рН =8,9.0.

According to the instruction attached to the block of automatic titration adjust him on a point of equivalence, equal 8,9 units рН, and establish on the block value рН =4,0 since which giving of a hydroxide of sodium has to be conducted on drops.

Determine hold time after the end of titration, equal 30 withПроведениеизмерений

Milk, milk-containing product, dairy compound product, cream, curdled milk, acidophilus milk, kefir, koumiss and other fermented milk products

In a glass with a capacity of 50 cm measure 20 cm of the distilled water and the 10th smanaliziruyemy product. Mix is carefully mixed.

In the analysis of cream and fermented milk products move the product remains from the pipette to a glass by washing of the pipette the received mix 3-4 times.

Place a core of the magnetic mixer in a glass and install a glass on the magnetic mixer. Turn on the engine of the mixer and immerse electrodes of the electrometric analyzer and a drain tube of the batcher of the block of automatic titration in a glass with a product. Turn on the Start-up button of the block of automatic titration, and later 2-3 with, the Endurance button. Sodium hydroxide solution at the same time begins to come from the block batcher to a glass with a product, neutralizing the last. On reaching an equivalence point (рН =8,9) and the expiration of hold time (30 c) neutralization process automatically stops, and on the panel of the block of automatic titration the signal "End" is lit. After that switch-off all buttons. Carry out counting of amount of solution of a hydroxide of the sodium spent for neutralization.

Processing of results

The acidity in Turner's degrees is found multiplication of volume, by cm, solution of a hydroxide of the sodium spent for neutralization of a certain volume of a product on the following coefficients

10 - for milk, a dairy compound product, cream, curdled milk, acidophilous milk, kefir, koumiss and other fermented milk products;

20 - for ice cream, sour cream, cottage cheese and cottage cheese products.

The limit of the accepted confidential probability blundered result of measurements at =0,95 makes, °Т:

±0,8 - for milk, a dairy compound product, cream, ice cream;

±1,2 - for curdled milk, acidophilous milk, kefir, koumiss and other fermented milk products;

±2,3 - for sour cream;

±3,2 - for cottage cheese and cottage cheese products.

The divergence between two parallel measurements shouldn't exceed, °Т:

1,2 - for milk, a dairy compound product, cream, ice cream;

1,7 - for curdled milk, acidophilous milk, kefir, koumiss and other fermented milk products;

3,2 - for sour cream;

4,3 - for cottage cheese and cottage cheese products.

Take arithmetic-mean value of results of two parallel definitions for final result of measurement, rounding result to the second decimal sign.

At a bigger divergence test is repeated with four parallel definitions. At the same time the divergence between an arithmetic average value of results of four definitions and any value from four results of definition shouldn't exceed, °Т:

0,8 - for milk, a dairy compound product, cream, ice cream;

1,2 - for curdled milk, acidophilous milk, kefir, koumiss and other fermented milk products;

2,3 - for sour cream;

3,2 - for cottage cheese and cottage cheese products.

At a bigger divergence prepare anew all reactants, carry out the state checking of the used devices and repeat test with four parallel definitions. In this case in the presence of a divergence, there are more above-stated values, performance of this work is charged to the operator of higher qualification.

Definition of yeast, pleseny - in accordance with GOST 10444.12.

Selection and half-cooking of tests

Sampling of foodstuff in accordance with GOST 26668, GOST 26809 and GOST 9225.

Preparation of tests of foodstuff for test in accordance with GOST 26669, GOST 9225.

Canned food checks for tightness in accordance with GOST 8756.18.

Full canned food, normal on appearance, before test termostatirut at 30-37 °C in a container with a capacity up to 1 dm inclusive not less than 5 days, in a container with a capacity over 1 dm - not less than 7 days.

Foodstuff in which the admissible amount of yeast and mold mushrooms is normalized, termostatirovaniya aren't subject.

The mass (volume) of the hinge plate intended for preparation of the gomogenat of a product or initial cultivation - not less than (10,0±0,1) g (cm).

Initial cultivations of products with a mass fraction of NaCl prepare more than 5% with use of peptonny water; initial cultivations of meat products are prepared with use of physiological solution. For preparation of the subsequent tenfold cultivations use peptonno-salt solution. Peptonny water and peptonno-salt solution are prepared in accordance with GOST 26669, physiological solution - in accordance with GOST 10444.1.

From test of foodstuff in which the amount of yeast and (or) mold mushrooms is normalized or from initial cultivation of foodstuff prepare a number of cultivations according to the admissible amount of yeast and (or) mold mushrooms specified in the specifications and technical documentation a concrete type of foodstuff.

Equipment, materials and reactants

Use the equipment, materials, reactants to carrying out tests in accordance with GOST 10444.1 and also the equipment, materials and reactants provided below:

- scales laboratory general purpose with metrological characteristics in accordance with GOST 24104 *, with the greatest limit of weighing to 200 g and at the testing cost of division no more than 2 mg (for weighing of reactants);

- scales laboratory general purpose with metrological characteristics in accordance with GOST 24104 *, with the greatest limit of weighing to 200 g and at the testing cost of division no more than 20 mg (for weighing of a product);

- the thermostat allowing to maintain temperature (24±1) of °C

- microscope light biological or other similar brands;

oil immersion for microscopy in accordance with GOST 13739;

- glasses subject in accordance with GOST 9284;

- glasses integumentary in accordance with GOST 6672;

- vatu medical hygroscopic in accordance with GOST 5556;

- agar serumal BF;

- bromfenolovy blue, water-soluble, indicator;

- gentamycin sulfate in bottles on 0,08 g or in ampoules on 1 or 2 cm

- water solution mass fraction of 4%;

- an oksitetratsiklina a dihydrate in tablets on 0,25 g (250000 PIECES);

- Neomycinum sulfate in bottles on 0,5 g (50000 PIECES) or in tablets on 0,10 and 0,25 g;

- medicines of group of a levomitsetin:

- medicines of group of penicillin:

- benzylpenicillin sodium salt or potassium salt in bottles on 250000, 500000 or 1000000 PIECES;

- benzylpenicillin novokainovy salt in bottles on 300000, 600000 or 1200000 PIECES;

- новоцин in bottles on 400000, 800000, 1200000 PIECES;

- medicines of group of streptomycin:

- streptomycin sulfate in bottles on 0,25 g (250000 PIECES), 0,5 g (500000 PIECES), 1 g (1000000 PIECES);

- a streptosulmitsina sulfate in bottles on 0,25, 0,5 or 1 g

- streptomycin - a chlorcalcium complex in bottles on 0,1, 0,2, 0,5 g;

- dihydrostreptomycin sulfate in bottles on 0,25, 0,5 or 1 g;

- dihydrostreptomycin pantothenate in bottles on 0,25 g (250000 PIECES), 0,5 g (500000 PIECES), 1 g (1000000 PIECES).

Preparation for test

Preparation of solutions of antibiotics

Solutions of antibiotics are prepared just before use.

Antibiotics in tablets use for preparation of solutions in the absence of antibiotics for injections. At preparation of solutions of antibiotics from tablets it isn't allowed to carry out weighing as tablets can contain different amount of filler. In this case preparation of solutions is based on use of the whole tablets with precisely known maintenance of antibiotics.

It is allowed in the analysis of foodstuff (except canned food) to carry out preparation of solutions of antibiotics from tablets with observance of rules of an asepsis on the sterile distilled water.

Solution mass concentration of gentamycin of sulfate of 10 g/dm:

from 80 mg of gentamycin of sulfate (for injections) bring 8 cm of the sterile distilled water in a bottle, dissolve contents of a bottle. Solution is added to a ready basis of the environment.

At sulfate gentamycin solution use in ampoules recognize that the ampoule with 1 cm of solution contains 40 mg of gentamycin, and from 2 cm - 80 mg.

Solution mass concentration of a levomitsetin of the suktsinat of soluble 50 and 100 g/dm: from 0,5 or 1,0 g of a levomitsetin (for an injection) bring 10 cm of the sterile distilled water in a bottle, dissolve contents of a bottle. Solutionisaddedtoareadybasisoftheenvironment.

When using a levomitsetin in tablets on 0,25 and 0,5 g prepare solutions by mass concentration of a levomitsetin of 5 g/dm. For this purpose 2 tablets on 0,25 g or 1 tablet on 0,5 g pound in a mortar, transfer to a measured flask with a capacity of 100 cm, washing away the distilled water, will sterilize by method of membrane filtration in accordance with GOST 26670. It is allowed to sterilize solution of a levomitsetin together with an environment basis.

Solution mass concentration of an oksitetratsiklin of a dihydrate of 1 g/dm: 1 tablet on 0,25 g is pounded in a mortar, transferred to a measured flask with a capacity of 250 cm, washing away the distilled water. Solution is brought to a tag the distilled water, sterilized by method of membrane filtration in accordance with GOST 26670.

Solutions of medicines of penicillin prepare at the rate of the maintenance of an antibiotic 50000 or 100000 PIECES in 1 cm of solution:

from 250000, 300000, 500000 PIECES bring in bottles according to 5, 6, 10 smsterilny the distilled water, dissolve contents of a bottle, receiving the solutions containing in 1 cm 50000 PIECES of an antibiotic;

from 1000000, 1200000 PIECES bring in bottles respectively 10, 12 cm of the sterile distilled water, receiving the solutions containing in 1 cm 100000 PIECES of an antibiotic.

Solutions of medicines of group of streptomycin mass concentration of an antibiotic of 100 g/dm: in bottles with 0,10; 0,25; 0,50 and 1 g of an antibiotic bring respectively 1; 2,5; 5; The 10th smsterilny distilled water, contents of a bottle are dissolved.

Solution mass concentration of Neomycinum of sulfate of 50 g/dm: from 0,5 g of Neomycinum of sulfate (for injections) bring 10 cm of the sterile distilled water in a bottle.

At solution preparation by mass concentration of Neomycinum of sulfate of 10 g/dm from tablets: 2 tablets on 0,25 g or 5 tablets on 0,1 g pound in a mortar, transfer powder to a measured flask on 50 cm, washing away the distilled water, bring volume to a tag. Solution will be sterilized by method of membrane filtration in accordance with GOST 26670.

Preparation of nutrient mediums

Nutrient mediums with antibiotics are prepared just before use.

At preparation of environments with antibiotics prepare bases of environments in the beginning. Add solutions of antibiotics to the basis of the environment melted and cooled up to the temperature (46±1) of °C.

For preparation of nutrient mediums with antibiotics use the following bases.

The basis of the environment (Saburo environment) is prepared as follows: 40,0 glucose, 10,0 g of peptone, 18,0 g of an agar add to 1 dm of the distilled water. Mix is warmed up, periodically stirring slowly, before fusion of components, cool up to 45-55 °C, established рН so that after sterilization he made at 25 °C 6,5±0,1, spill in measured flasks and sterilized 15 min. at a temperature (121±1) of °C. A basis of the environment store at a temperature (4±2) °C no more than 14 days.

The basis of the environment (Saburo environment) is allowed to be used without addition of antibiotics in the analysis of canned food on industrial sterility.

Environment basis from a dry serumal agar of BF.

Are a part of Wednesday:

- the dry hydrolyzed mix 37,0

- potassium fosfornokisly monosubstituted 0,8

- sodium fosfornokisly monosubstituted 0,04

- bromfenolovy blue, water-soluble, the indicator 0,16

- an agar 22,0.

60,0 g of a dry serumal agar of BF add to 1 dm of the distilled water, heat to full dissolution (in the presence of a deposit filter). Establish рН so that after sterilization at 25 °C he made 4,2±0,2. A certain volume of the environment is spilled in flasks and sterilized at a temperature (121±1) of °C within 15 min.

The basis of the environment is used in the analysis of milk and dairy products.

Wednesday agarizovanny with levomitsetiny: add 2 cm of solution of a levomitsetin of the suktsinat to 1 dm of a basis soluble (for injections) mass concentration of 50 g/dm or 1 cm of solution mass concentration of 100 g/dm when using solution of a levomitsetin of mass concentration of 5 g/dm add 20 cm of solution to 980 cm of a basis.

Wednesday agarizovanny with oksitetratsikliny: add 100 smrastvor of an oksitetratsiklin of a dihydrate to 900 cm of a basis mass concentration of 1 g/dm

Wednesday agarizovanny with oksitetratsikliny and gentamycin: add 100 cm of solution of an oksitetratsiklin of a dihydrate to 895 cm of a basis mass concentration of 1 g/dm and 5 cm of solution of gentamycin mass concentration of 10 g/dm.

Wednesday agarizovanny with antibiotics of group of penicillin and streptomycin: add 1 or 0,5 cm of solution of an antibiotic of group of the penicillin containing respectively 50000 or 100000 PIECES to 1 dm of a basis then by Wednesday add 0,4 cm of solution of an antibiotic of group of streptomycin mass concentration of 100 g/dm.

Carrying out test

From the prepared test of a product and (or) its cultivation select a hinge plate volume (1±0,1) see.

Product and (or) its cultivations sow in accordance with GOST 26670 in parallel in two cups Understand. Crops fill in melted and cooled up to the temperature (45±1) of °C Wednesday.

In parallel with it fill in a cup And Understand 15-20 cm of the environment for check of its sterility.

It is allowed at establishment of industrial sterility of canned food and at identification of activators of damage in products on 2,0 cm of the studied material to sow in parallel in two test tubes from 5 cm of a liquid malt mash.

Crops termostatirut at a temperature (24±1) of °C during 5 days, Understand crops on cups termostatirut a bottom up.

In 3 days of a termostatirovaniye carry out preliminary accounting of typical colonies or emergence of characteristic signs of growth on liquid nutrient mediums.

If at crops on the agarizovannykh Wednesdays there are mukorovy, very quickly growing mushrooms, then removal of preliminary results needs to be carried out very carefully, without assuming that disputes of these mushrooms were showered and have given growth of secondary colonies. In 5 days carry out final accounting of results of a termostatirovaniye of crops. Colonies of yeast and mold mushrooms divide visually.

Growth of yeast on the agarizovannykh is followed Wednesdays by formation of large, convex, brilliant, grayish-white colonies with a smooth surface and a smooth edge. Development of yeast in the liquid environment is followed by emergence of dregs, a smell of fermentation and gas.

Development of mold mushrooms on nutrient mediums is followed by emergence of a mycelium of various coloring.

For quantitative calculation select cups on which from 15 to 150 colonies of yeast and (or) from 5 to 50 colonies of mold mushrooms have grown.

If necessary for division of colonies of yeast and mold mushrooms conduct microscopic researches.

For this purpose from separate colonies or from crops on the liquid environment prepare medicines by method of the crushed drop. Apply a drop of sterile tap water on subject glass. Then in this drop the calcinated needle brings a part of colony or with a loop put a drop of cultural liquid. The received suspension becomes covered with integumentary glass.

Results of a mikroskopirovaniye estimate using the characteristic of yeast and mold mushrooms specified in the appendix.

Processing of results

Results estimate on each test separately.

If at test of a product on nutrient mediums growth of yeast and mold mushrooms is found and their presence is confirmed with a mikroskopirovaniye, then draw the conclusion about presence of these microorganisms at a product.

Results process and recalculate separately for yeast and mold mushrooms.The amount of yeast and mold mushrooms in 1 g or in 1 cm of a product calculate on a formula:

(11)

(11)

where  -the sum of all counted colonies on cups Understand in two consecutive tenfold cultivations provided that on each cup the number of colonies meets the requirements.

-the sum of all counted colonies on cups Understand in two consecutive tenfold cultivations provided that on each cup the number of colonies meets the requirements.

-Understand the number of cups, counted for smaller cultivation, i.e. for more concentrated cultivation of a product;

-Understand the number of cups, counted for smaller cultivation, i.e. for more concentrated cultivation of a product;

- Understand the number of cups, counted for bigger cultivation;

- Understand the number of cups, counted for bigger cultivation;

n - extent of cultivation of a product (for smaller cultivation). Results of test are written down according to requirements of GOST 26670..

- Definition of a mass fraction of protein - in accordance with GOST 23327

Sampling methods

Methods of sampling and preparation them to the analysis - in accordance with GOST 13928 and GOST 26809.

Equipment, materials and reactants

Apply the following to measurements the equipment, materials and reactants:

- scales laboratory the 2nd class of accuracy with the greatest limit

- weighings of 200 g in accordance with GOST 24104;

- scales laboratory the 4th class of accuracy with the greatest limit

- weighings of 500 g in accordance with GOST 24104;

- the analyzer electrometric with a range of measurement of 0-12 units рН, with the price of division of 0,05 units рН;

- the block of automatic titration, it is hardware the compatible to the electrometric analyzer and having solution batcher - the burette with a capacity not less than 5 cm, with the division price no more than 0,02 cm and also the magnetic mixer;

- an automatic kulonometrichesky titrator of general purpose with a range of measurement of 0,1-0,4 C and at the cost of division no more than 0,005 C or an automatic kulonometrichesky titrator for measurement of a mass fraction of the general nitrogen with a range of measurement of 0%-1% of nitrogen and at the cost of division no more than 0,01% of nitrogen;

- the thermometer mercury glass with a range of measurement of 0 °C - 40 °C and at the cost of division of 0,1 °C in accordance with GOST 28498;

- tile electric 1000 W in accordance with GOST 14919;

- the block with nests aluminum for test tubes or flasks;

- hoodthe device for removal of the acid vapors which are emitted at a mineralization;

- Kyeldal's flasks 2-100-TC in accordance with GOST 25336;

- test tubes quartz the BP type in accordance with GOST 19908 or test tubes from heat-resistant glass;

- flasks measured 1-250-2, 1-500-2, 1-1000-2, 1-2000-2 or 2-250-2, 2-500-2, 2-1000-2, 2-2000-2 in accordance with GOST 1770;

- cylinders measured 1-10-1, 1-50-1, 1-100-1, 1-1000-1 or 1-10-2, 1-50-2, 1-100-2, 1-1000-2 or 3-50-1, 3-100-1, 3-1000-1 or 3-50-2, 3-100-2, 3-1000-2 in accordance with GOST 1770;

- pipettes 8-2-0,1 or 8-2-0,2 in accordance with GOST 29228;

- pipettes 6-1-10 or 6-2-10 in accordance with GOST 29228;

- burettes 1-2-5-0,02 or 2-2-5-0,02 or 6-2-5-0,02 or 7-2-10-0,02 in accordance with GOST 29228;

- flasks conic Kn-2-250-34THS, Kn-2-1000-42-THS, Kn-2-2000-50-TS in accordance with GOST 25336;

- glasses of B-1-50 of the CU, B-1-100 of the CU, B-1-250 of the CU or B-2-50 of the CU, B-2-100 of the CU, B-2-250 of the CU in accordance with GOST 25336.

Preparation for measurements

Sodium hydroxide solution preparation

Dissolve 400 g of a hydroxide of sodium in 600 cm of the distilled water.

Preparation of mix of salts

Mix 100 g of sulfate of potassium from 0,4 g of sulfate copper, crush mix in a mortar.

Preparation of solution of indicators

Dissolve in 100 cm of acetone: for receiving methylene blue - 0,075 g of methyl red and 0,200 g methylene blue; bromkrezolovy green - 0,045 g of methyl red and 0,200 g bromkrezolovy green and diamond green - 0,045 g of methyl red and 0,010 g diamond green.

Preparation of solution for ammonia absorption

For measurement of a mass fraction of nitrogen with indication of a point of equivalence by means of the electrometric analyzer dissolve 40 g of boric acid in 1000 cm of the hot distilled water.

For measurement of a mass fraction of nitrogen with indication of a point of equivalence on change of coloring of the indicator bring 25 cm of one of indicator solutions in 1000 cm of solution of boric acid.

Preparation of solution of hydrochloric acid of concentration of 0,2 mol/dm

According to the instruction to the standard caption bring contents of two ampoules the standard caption of hydrochloric acid in a measured flask with a capacity of 1000 cm, bring the distilled water volume to a tag and mix.

Preparation of anode solution

Place in a measured flask with a capacity of 1 dm 100 g of bromide of potassium, 200 g of a hydrocarbonate of potassium and 22 g of a carbonate of potassium, flow 800 cm of the distilled water and mix before dissolution. The volume of solution is brought to a tag water and mixed.

Preparation of neutralized solution

Place 100 g of bromide of potassium and 240 g of a hydroxide of sodium in a measured flask with a capacity of 1 dm, flow about 800 cm of the distilled water and mix before dissolution. The volume of solution is brought to a tag water and mixed.

Carrying out measurements.

Place several pieces of glass tubes in Kyeldal's flask or a test tube and 10 g of mix of salts.

In a glass for weighing measure 1 cm of a product, close a cover and weigh. The product is poured in Kyeldal's flask or a test tube. The empty glass with a cover is weighed again and on a difference between the mass of a glass with milk and mass of an empty glass establish the mass of the taken product.

Add 10 cm of sulfuric acid and 10 cm of peroxide of hydrogen or 0,5 g of permanganate of potassium to Kyeldal's flask or a test tube.

Kyeldal's flask or test tube are placed in a nest of the aluminum block on the rangette.

Kyeldal's flask or test tube with received mineralizaty are cooled on air to room temperature.

Measurement of a mass fraction of the general nitrogen with indication of a point of equivalence on change of coloring of the indicator is taken in the chemical way in the following sequence.

With mineralizaty add the 20th smdistillirovanny water to Kyeldal's flask or a test tube and carefully mix with circular motions before dissolution of a deposit.

Assemble the distillation device. Turn on the rangette under a flask steam generator, open a clip on the line of removal of steam in the sewerage and close a clip on the line of supply of steam in Kyeldal's flask. Heat water in a flask steam generator to boiling. Kyeldal's flask or a test tube are attached to the distillation device.

In a conic flask with a capacity of 250 cm measure the measured cylinder 20 of a smsmesa of solution of boric acid with indicator solution.

Install a conic flask on poses.7 (figure 5) so that the end of a tube of the refrigerator was below the top level of mix of solutions in a flask.

Measure the measured cylinder 50 cm of solution of a hydroxide of sodium and it is careful, without allowing emissions, pour it through a delitelny funnel in Kyeldal's flask or a test tube. The funnel crane is closed at once. Close a clip on the line of removal of steam and open a clip on the line of supply of steam from a flask steam generator in Kyeldal's flask or a test tube.

Distillation conduct before achievement of volume of condensate 90-120 cm (distillation time - 5-10 min.). Water temperature at the exit from the refrigerator shouldn't exceed 25 °C.

Contents of a conic flask with solution of the indicator, boric acid and condensate are titrut solution of hydrochloric acid concentration by 0,2 mol/dm before change of color,

Processing of results of measurements.

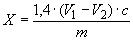

The mass fraction of the general nitrogen at a chemical way of measurement is calculated on a formula:

(12)

(12)

Where  - the acid volume spent for titration at control measurement;

- the acid volume spent for titration at control measurement;

- the acid volume spent for titration, cm;

- the acid volume spent for titration, cm;

c - concentration of hydrochloric acid;,  ;

;

m - mass of a hinge plate of a product ;

1,4 - coefficient of recalculation of volume of acid in a mass fraction of the general nitrogen  .

.

Mass fraction of protein  , %, determine by a formula

, %, determine by a formula

(13)

(13)

Where 6,38 - the mass of milk protein equivalent to unit of mass of the general nitrogen.

Mass fraction of the general nitrogen, at an electrochemical way of measurement calculate on the formula given in the passport of the device.

Дата добавления: 2018-06-27; просмотров: 356; Мы поможем в написании вашей работы! |

Мы поможем в написании ваших работ!