Discuss methods for the obtaining of graft copolymers by grafting-onto, grafting-from and grafting-through approaches

Of the several controlled/”living” free radical polymerization techniques, Atom Transfer Radical Polymerization (ATRP) seems to be the most versatile, being able to polymerize a variety of monomers, method to prepare block and graft copolymers. ATRP enables the synthesis of a wide range of (co)polymers with controlled molecular weight, narrow molecular weight distribution, and range of architectures and functionalities.

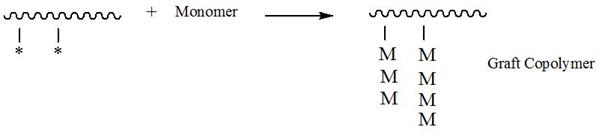

Graft copolymers are another class of segmented copolymers. Many basic characteristics of block copolymers and graft copolymers are similar and no major difference exists between block copolymer synthesis and graft copolymer synthesis. The location of sites and functions are at the chain ends or on the chains, respectively:

“Grafting” is a method where in monomers are covalently bonded (modified) onto the polymer chain. Graft copolymers can be obtained with three general approachs:

1. Grafting-onto: A preformed polymer with a reactive end-group is used a precursor, and then attached to the backbone. This method involve reaction of functional groups (Y) located at chain ends of one kind of polymer with another functional groups (X) which distributed randomly on the main chain of the other polymer (backbone).

2. Grafting-from: The monomer is grafted from the backbone. “Grafting-from” is significantly more versatile than “grafting-onto”.

3. Grafting-through in other words grafting via surface-attached monomers (macromonomers): In this approach, polymerizations are carried out at the presence of polymers (backbone) onto which functionalized monomers have been attached. The surface-attached monomers are incorporated into growing polymer chains in the same way as the monomers in solution (the monomers in solution are usually different from the surface-attached ones).

Discuss methods for the synthesis of well-defined multi-block copolymers by alternation copolymerization.

Copolymers are a variety of polymers whose molecular chains consist of two or more different structural units. There are regular and irregular copolymers. The various structural links of the irregular copolymers are randomly arranged along the chain. In regular copolymers, the various structural units are arranged in an ordered manner, and therefore regular copolymers can be represented as conventional polymers with large structural units. Separately, block copolymers consisting of several (homo) polymer blocks can be named. Copolymers are obtained as a result of copolymerization reactions.

Copolymerization is a polymerization in which two or more different monomers participate. As a result of copolymerization, copolymers are formed, whose macromolecules consist of two or more dissimilar structural units. Copolymerization makes it possible to obtain high-molecular substances with various properties.

The monomers from which the copolymers are made can be combined in different ways. The most likely ways:

* Alternating (A-B) n

* periodic (A-B-A) n

* statistical (A-A-B-A-A-A-B-B-A-B)

* block copolymer (A) n - (B) m

Discuss methods for the synthesis of star polymers by “core first” and “arm first” approaches.

Star polymers consist of several linear polymer chains connected at one point. There are several approaches that can be employed for synthesis of star copolymers. As suggested above, star polymers can be synthesized by variations on one of 2 methods:

o The "core-first" approach, where the controlled polymerization is conducted from either a well defined initiator with a known number of initiating groups or a less well defined multifunctional macromolecule.

o There are two approaches to the "arm-first" synthesis of star polymers. One is where a linear "living" copolymer chain, or added macroinitiator, is linked by continuing the copolymerization of the mono-functional macroinitiator with a divinyl monomer forming a crosslinked core.

Core first: The following section on nano-composites formed by grafting from the surface of a functionalized particle is an evolution of the "core first" approach to synthesis of star macromolecules. Initially a low molecular weight multi-functional molecule was used in a "grafting from" reaction to form star macromolecules with a well defined number of arms.

Arm first: Macroinitiator approach:

The "arm first" approach forms the core of the star macromolecule by coupling monofunctional "living" polymeric chains with a difunctional reagent and was first applied to living anionic polymerization. A similar approach was also successful using ATRP. Initially the simple chain extension of a linear macroinitiator with a crosslinker provided star macromolecules with broad polydispersity as a result of star-star coupling reactions.

Macromonomer Approach:

Another approach to arm first star copolymers, with available core containing initiating functionality, is the CRP of higher molecular weight macromonomers in a pure homo-polymerization initiated with a small molecule initiator which usually leads to a "brush molecule".

Discuss methods for the synthesis of block copolymers by living anionic polymerization. Evaluate advantages and disadvantages of these methods in comparison with main techniques of living radical copolymerization.

Синтез блоксополимеров из мономеров.

a) through living polymers.

An anionic or anionically coordinated catalyst is used.

Example. Non-polar environment, Li- organic catalyst, monomers: butadiene (isoprene) + styrene.

Monomers: butadiene and styrene are fed either simultaneously or alternately.

If at the same time, blocks from the units of the more active monomer are formed first, then from the less active monomer.

If, in turn, first, living blocks of one monomer are formed, upon exhaustion, a second monomer is introduced.

Alternating the feeding of monomers, it is possible to obtain a block copolymer with different numbers and sizes of blocks. Usually, the molecular weight of polystyrene blocks is from 2000 to 100000, and of polybutadiene blocks is from 5000 to 200000. An anionic block of CPF is used to prepare triple block copolymers.

Mechanism of copolymerization:

"Living" polystyrene

double copolymer

The transformation of the double copolymer into a triple is carried out in two ways:

a) using a binding agent  б) adding a new portion of the monomer (e.g., styrene)

б) adding a new portion of the monomer (e.g., styrene)

Alternating non-crystallizing blocks of a random copolymer with blocks of crystallizable homopolymers (polyethylene PE or polypropylene PP), thermoplastic elastomers are obtained. Their main characteristics are: high density, ductility with increasing temperature. They are well processed. The thermoplastic elastomers also include block copolymers of isoprene or butadiene with styrene. After the polymerization of styrene, butadiene is added to the end of the macroanion chain, which copolymerizes with a block of polystyrene, and the macroanion remains at the end of the chain. When a new portion of styrene is added, a third block is formed within the same macromolecule. The obtained styrene-butadiene-styrene block copolymers (SBS) have valuable properties: they are strong and elastic at room temperature and thermoplastic at elevated temperatures (80-100 ° C). Of these, products are prepared for the medical industry, soles for shoes and other products where high thermal stability is not required, but strength and high elasticity at room and lower temperatures are needed.

Дата добавления: 2018-04-04; просмотров: 320; Мы поможем в написании вашей работы! |

Мы поможем в написании ваших работ!