Find the English equivalents for the following phrases

Unit 8

INDUSTRIAL EQUIPMENT: FRACTIONATION

Read and translate the international words

Figure, fractionation, industrial, interval, condensation, material, vacuum, operation, condenser, contact, progress, distillate, physical, physics, physicist, schematic.

Read and translate the verbs

To depict, to withdraw, to exit, to enter, to achieve, to refer, to return, to show, to cool, to heat, to drop, to operate, to progress, to decrease, to succeed, to offer.

Match the English word combinations in column A to their Russian equivalents in column B

| А | B |

| 1. fractionation column 2. external reflux 3. upflowing vapor 4. downflowing liquid 5. bubble-cap 6. packing material 7. boiling range 8. outlet 9. reflux drum 10. receiver 11. offgas line 12. tray 13. feed stream 14. boiling material | a) восходящие пары b) колпачок барботажной колонны c) насадка d) выходное отверстие e) сборник орошающей фракции f) кипящий материал g) линия отходящего газа h) сборник i) ректификационная колонна j) сырьевой поток k) тарелка ректификационной колонны l) нисходящая жидкость m) внешнее орошение n) интервал кипения |

Read and translate

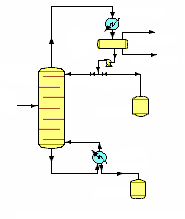

Figure 8.1 depicts an industrial fractionation column separating a feed stream into one distillate fraction and one bottom fraction. However, many industrial fractionation columns have outlets at intervals up the column so that multiple products having different boiling ranges may be withdrawn from a column distilling a multicomponent feed stream. The lightest products with the lowest boiling points exit from the top of the columns and the heaviest products with the highest boiling points exit from the bottom. Industrial fractionating columns use external reflux to achieve better separation of products. Reflux refers to the portion of the condensed overhead liquid product that returns to the upper part of the fractionating column as shown in figure. Inside the column, the downflowing reflux liquid provides cooling and condensation of upflowing vapors thereby increasing the efficacy of the distillation tower. The more reflux and more trays provided, the better is the

tower’s separation of lower boiling materials from higher boiling materials. Bubble-cap “trays” or “plates” are one of the types of physical devices which are used to provide good contact between the upflowing vapor and the downflowing liquid. In industrial uses, sometimes a packing material is used in the column instead of trays, especially when low pressure drops across the column are required, as when operating under vacuum.

tower’s separation of lower boiling materials from higher boiling materials. Bubble-cap “trays” or “plates” are one of the types of physical devices which are used to provide good contact between the upflowing vapor and the downflowing liquid. In industrial uses, sometimes a packing material is used in the column instead of trays, especially when low pressure drops across the column are required, as when operating under vacuum.

|

|

|

Fig. 8.1. The schematic of a continuous fractionating column

Decide whether the statements below are true or false according to the information in exercise 4

1. The lightest products with the lowest boiling points exit from the bottom of the column.

2. To achieve better separation of products, fractionating columns use external reflux.

3. The contact between upflowing and downflowing streams in the column is always good, so no additional physical devices are needed.

4. The less reflux and more trays are provided, the better is the tower’s separation.

5. Fractionation columns are used for mixing various liquid compounds.

6. The temperature conditions are the main characteristic of a fractionation column.

Find the English equivalents for the fractionation process components listed below. Describe the fractionation process

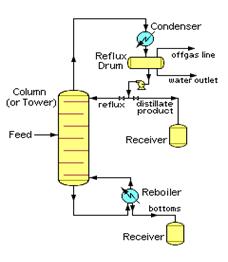

Рис.8.2. Схема ректификационной колонны непрерывного действия | 1. сборник 2. кубовый продукт 3. продукт перегонки 4. колонна 5. подача исходного продукта 6. сборник орошающей фракции 7. ребойлер 8. конденсатор 9. линия отходящего газа 10. водосброс 11. орошение ректификационной колонны |

Read and translate

Исходная смесь (жидкость), состоящая из двух компонентов, поступает в колонну. Ректификационная колонна имеет цилиндрический корпус, внутри которого установлены контактные устройства в виде тарелок. Из ребойлера (кипятильника) в нижнюю часть колонны поступают пары, которые движутся вверх. Это восходящий поток. Пары проходят через слой жидкости на тарелках. Компонент смеси, имеющий меньшую точку кипения, в виде пара поступает в верхнюю часть колонны, а затем в конденсатор, где конденсируется. Полученная жидкость, проходя через сборник орошающей фракции, подается на верхнюю тарелку колонны. Это нисходящий поток. Жидкость, выходящая из нижней части колонны делится на две части. Одна часть направляется в кипятильник, другая – в сборник.

|

|

|

Read and translate

Fractionation towers use various liquid contacting methods to provide the required number of equilibrium stages. Such devices are commonly known as “plates” or “trays”. Each of these plates or trays is at different temperature and pressure. The stage at the tower bottom has the highest pressure and temperature. Progressing upwards in the tower, the pressure and temperature decreases for each succeeding stage.

Another way of improving the separation in a distillation column is to use packing material instead of trays. These offer the advantage of a lower pressure drop across the column.

Https://en.wikipedia.org/wiki/Continuous_distillation

Read and translate

The column can be fed in different ways. If the feed is from a source at a pressure higher than the fractionation column pressure, it is simply piped into the column. Otherwise, the feed is pumped or compressed into the column. The feed may be a superheated vapor, a saturated vapor, a partially vaporized liquid-vapor mixture, a saturated liquid or a sub-cooled liquid. If the feed is a liquid at a much higher pressure than the column pressure and flows through a pressure let-down valve just ahead of the column, it will immediately expand and undergo a partial flash vaporization resulting in a liquid-vapor mixture as it enters the fractionation column.

|

|

|

Https://en.wikipedia.org/wiki/Continuous_distillation

Find the English equivalents for the following phrases

Дата добавления: 2019-01-14; просмотров: 93; Мы поможем в написании вашей работы! |

Мы поможем в написании ваших работ!