История возникновения сварочного производства

Read and remember :

| № | English | Transcription | Translation | ||

| 1 | Joining |

| Соединение | ||

| 2 | Welding |

| Сварка | ||

| 3 | Article |

| Деталь | ||

| 4 | Depending |

| Зависит от | ||

| 5 | Joint | Шов, соединение | |||

| 6 | Strength |

| Прочность | ||

| 7 | To be required |

| Требуется | ||

| 8 | Soldering |

| Пайка | ||

| 9 | To river |

| Клепать, склёпывать | ||

| 10 | Permanent |

| Постоянный | ||

| 11 | Heating |

| Нагрев | ||

| 12 | Flame |

| Пламя, сгорание | ||

| 13 | To hammer |

| Ковать | ||

| 14 | Weld |

| Сварочный шов, сварочное соединение | ||

| 15 | Care must be taken to ensure |

| Необходимо убедиться | ||

| 16 | Dirt |

| Грязь | ||

| 17 | To weaken |

| Ослаблять | ||

| 18 | To cause |

| Вызывать | ||

| 19 | Oxidation |

| Окисление | ||

| 20 | Film oxide |

| Плёнка частиц окиси | ||

| 21 | Flux |

| Флюс | ||

| 22 | To dissolve |

| Растворяться | ||

| 23 | To apply |

| Применять | ||

| 24 | Impurities |

| Примести | ||

| 25 | To squeeze |

| Выдавливать | ||

| 26 | Vel – shaped | Образный | |||

| 27 | Butt – weld | Сварка в стык | |||

| 28 | Lap – weld |

| Сварка в нахлёст | ||

| 29 | To generate |

| Получить | ||

| 30 | Xy – acetylene torch |

| Ацетиленовая горелка | ||

| 31 | Filler rod |

| Присадочный прудок | ||

| 32 | Spot welding |

| Точечная сварка | ||

| 33 | Overlap |

| Перекрытие | ||

| 34 | Laser welding |

| Лазерная сварка | ||

| 35 | Electronic flam welding |

| Электронно – лучевая сварка | ||

| 36 | Arc |

| Дуга | ||

| 37 | Arc welding |

| Дуговая сварка | ||

1. Read the following Text:

WELDING

1. Welding is a process of joining together metallic parts by heating the place of contact to the fusion state.2. Welding processes are classified according to the source of energy employed for heating, the metals and the state of the metal at the place of welding.3. There are different types of welding such as hammer welding, thermit welding, electric arc welding, gas welding, etc.4. Hammer welding is a process in which two heated metal parts are joined and fused together by force from a power hammer.5. Thermit welding is a process consisting of a chemical reaction. 6. It is used in repairing large sections such as rails, frames, etc.7. Resistance welding process forms a whole group consisting of many types of welding such as spot welding, butt welding and others.8. In arc welding the workpieces are not melted by a flame. 9. They are melted by an electric arc. In order to create the arc, a powerful electric current must be provided. 10. The current must be at least 60 A, otherwise the arc will not create enough heat.11. In gas welding, it is necessary to use a mixture of two gases. 12. To create a hot flame, a combustible gas must be mixed with oxygen.13. Gas welding is normally used to join steel to steel.

|

|

|

Translate the Text in writing.

Put 7 general questions to the Text.

Retell the main idea from the Text.

Home Test

Ex.1 Match the sides:

| № | English | Transcription | Translation | ||||

| 1 | Joining |

| a) Постоянный | ||||

| 2 | Welding |

| b) Деталь | ||||

| 3 | Article |

| c)Ацетиленовая горелка | ||||

| 4 | Depending |

| d)Плёнка частиц окиси | ||||

| 5 | Joint |

| e)Ковать | ||||

| 6 | Strength | f) Соединение | |||||

| 7 | To be required |

| g)Образный | ||||

| 8 | Soldering |

| h)Флюс | ||||

| 9 | To river |

| i)Сварка | ||||

| 10 | Permanent |

| j)Грязный | ||||

| 11 | Heating |

| k)Зависит от | ||||

| 12 | Flame |

| l)Пламя, сгорание | ||||

| 13 | To hammer

|

| m)Шов, соединения | ||||

| 14 | Weld |

| n)Растворятся | ||||

| 15 | Care must be taken to ensure |

| o)Прочность | ||||

| 16 | Dirt |

| p)Нагрев | ||||

| 17 | To weaken |

| q)Точечная сварка | ||||

| 18 | To cause |

| r)Перекрытия | ||||

| 19 | Oxidation |

| s)Требуется | ||||

| 20 | Film oxide |

| t)Примеси | ||||

| 21 | Flux |

| u)Дуга | ||||

| 22 | To dissolve |

| v)Получить | ||||

| 23 | To apply |

| w)Пайка | ||||

| 24 | Impurities |

| x)Примеси | ||||

| 25 | To squeeze |

| y)Клепать, склёпывать | ||||

| 26 | Vel – shaped |

| z)Сварочный шов, сварочное соединение | ||||

| 27 | Butt – weld | й)Необходимо убедиться | |||||

| 28 | Lap – weld |

| ю)Присадочный пруток | ||||

| 29 | To generate |

| я)Лазерная сварка | ||||

| 30 | Xy – acetylene torch |

| ї)Электрон но – лучевая сварка | ||||

| 31 | Filler rod |

| г)Сварка в нахлёстку | ||||

| 32 | Spot welding |

| з)Окисление | ||||

| 33 | Overlap |

| ш)Вызывать | ||||

| 34 | Laser welding |

| щ)Выдавливать | ||||

| 35 | Electronic flam welding |

| ь)Сварка в стык | ||||

| 36 | Arc |

| ъ)Ослаблять | ||||

Ex.2 Choose the right variant.

| 1. Welding: a ) пайка; b ) шов; c ) сварка . | 2. Strength: a) A) прочность; b) B) длина; c) c) ширина. | 3. Heating: a) охлаждение; b) нагрев; c) плавка | 4. To apply: a) A) крепить; b) B) соединять; c) C) применять. |

VOCABULARY

v неразъемное соединение – a solid bond;

v технология – process, technology;

|

|

|

v угольный электрод – carbon electrode;

v точечная сварка – spot welding;

v роликовая сварка – roller welding;

v контактная сварка – resistance welding;

v припой – solder;

v переменный ток – alternating current;

v постоянный ток – direct current;

v легированный – alloyed;

v добавка – additive;

v увеличиваться / уменшаться (о токе) – to amplify / to attenuate.

***

Как выполняются сварочные процессы

Text 1.

Welding.

1. Read and translate the text.

Welding is a process when metal parts are joined together by the application of heat, pressure, or a combination of both. The processes of welding can be divided into two main groups:

•pressure welding, when the weld is achieved by pressure and

•heat welding, when the weld is achieved by heat. Heat welding is the most common welding process used today.

Nowadays welding is used instead of bolting and riveting in the construction of many types of structures, including bridges, buildings, and ships. It is also a basic process in the manufacture of machinery and in the motor and aircraft industries. It is necessary almost in all productions where metals are used.

The welding process depends greatly on the properties of the metals, the purpose of their application and the available equipment. Welding processes are classified according to the sources of heat and pressure used: gas welding, arc welding, and resistance welding. Other joining processes are laser welding, and electron-beam welding.

Vocabulary

pressure welding сварка давлением

heat welding сварка нагревом

instead вместо, взамен

bolting скрепление болтами

riveting клепка

basic основной

to manufacture изготовлять

to depend зависеть от

purpose цель

gas welding газосварка

arc welding электродуговая сварка

|

|

|

resistance welding контактная сварка

laser welding лазерная сварка

electron-beam welding электронно-лучевая сварка

Answer the questions.

1. How can a process of welding be defined?

2. What are the two main groups of processes of welding?

3. How can we join metal parts together?

4. What is welding used for nowadays?

5. Where is welding necessary?

6. What do the welding processes of today include?

Find in the text.

1. Сегодня сварка используется вместо соединения болтами.

2. Сварочный процесс в основном зависит от свойств металла.

3. Она необходима почти во всех производствах, где используется металл.

4. Сварка нагреванием – самый распространенный процесс сварки сегодня.

5. Это основной процесс в машиностроении.

Find 8 words and write them.

Read in the text.

1. …… are laser welding, and electron-beam welding.

2. …… in all productions where metals are used.

3. …… on the properties of the metals.

4. …… or a combination of both.

5. …… when the weld is achieved by heat.

Welding methods

(типы сварки)

1. Read and translate the text.

There are three basic welding methods: manual, semiautomatic and automatic.

Manual welding is the oldest method, and though its proportion of the total welding market diminishes yearly, it is still the most common. Here an operator takes an electrode, clamped in a hand-held electrode holder, and manually guides the electrode along the joint as the weld is made. Usually the electrode is consumable; as the tip is consumed, the operator manually adjusts the position of the electrode to maintain a constant arc length.

Semiautomatic welding is becoming the most popular welding method. The electrode is usually a long length of small-diameter bare wire, usually in coil form, which the welding operator manually positions and advances along the weld joint. The consumable electrode is normally motor-driven at a preselected speed through the nozzle of a hand-held welding gun or torch.

Automatic welding is very similar to semiautomatic welding, except that the electrode is automatically positioned and advanced along the prescribed weld joint. Either the work may advance below the welding head or the mechanized head may move along the weld joint.

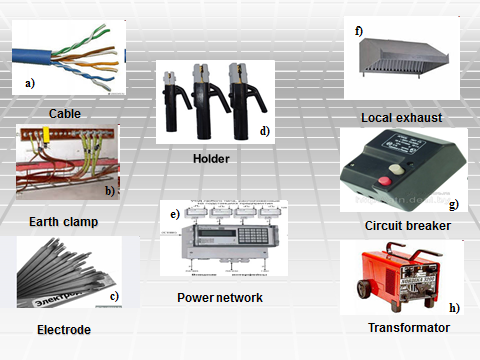

Vocabulary

Сable кабель

Еarth clamp заземление

Еlectrode электрод

Holder держатель

Transformator трансформатор

Power network сеть электропитания

Сircuit breaker выключатель тока

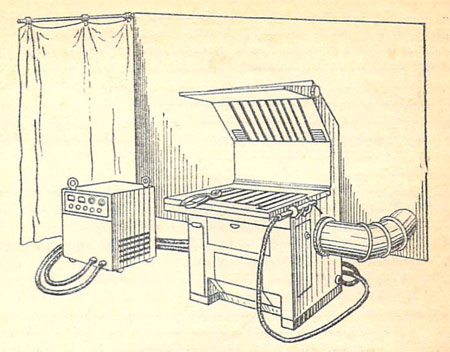

local exhaust зонт местной вытяжки

2. True or False?

1. Manual welding is the newest method.

2. A welder can use manual position during semiautomatic welding.

3. Semiautomatic welding is the most popular welding method because the weld joint is accurate.

4. Semiautomatic welding is not the most popular welding method.

5. The welding operator manually adjusts the position of the electrode to

maintain a constant arc length.

3. Welding methods and descriptions.

1. manual 2. semiautomatic 3. automatic

a. the work may advance below the welding head or the mechanized head

b. the operator manually adjusts the position of the electrode to arc length

c. the oldest method

d. the electrode is usually a long length of small-diameter bare wire

e. the consumable electrode is normally motor-driven at a preselected speed

f. the electrode is automatically positioned and advanced along the prescribed weld joint.

Find in the text.

1. берёт электрод

2. зажимаемый в электрододержателе для ручного сварочного процесса

3. вручную проводить электродом по стыку

4. вручную регулировать положение электрода

5. поддерживать стабильную длину дуги

6. электрод большой длины с маленьким диаметром голой проволоки в форме катушки

7. плавящийся электрод механизируется на заданной скорости через сопло ручной сварочной горелки или сварочного пистолета

8. сварочная или механизированная головка

5. Read in the text.

1. …. is very similar to semiautomatic welding.

2. …. the electrode is consumable; as the tip is consumed.

3. …. of a hand-held welding gun or torch.

4. …. an operator takes an electrode.

5. …. it is still the most common.

Kinds of welding

( типы сварки )

1. Read and translate the texts.

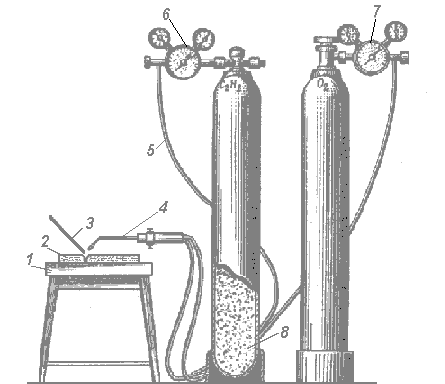

Gas Welding.

Gas welding is a non-pressure process using heat from a gas flame. The flame is applied directly to the metal edges to be joined and simultaneously to a filler metal in the form of wire or rod, called the welding rod, which is melted to the joint. Gas welding has the advantage of using equipment that is portable and does not require an electric power source. The surfaces to be welded and the welding rod are coated with flux, a fusible material that shields the material from air, which would result in a defective weld.

Arc Welding

Arc-welding is the most important welding process for joining steels. It requires a continuous supply of either direct or alternating electrical current. This current is used to create an electric arc, which generates enough heat to melt metal and create a weld.

Arc welding has several advantages over other welding methods. Arc welding is faster because the concentration of heat is high. Also, fluxes are not necessary in certain methods of arc welding. The most widely used arc-welding processes are shielded metal arc, gas-tungsten arc, gas- metal arc, and submerged arc.

Vocabulary

flame пламя

edge край

simultaneously одновременно

filler наполнитель

wire проволока

rod прут, стержень

to melt плавить(ся)

joint соединение, стык

coated покрытый

Answer the questions.

1. What do the welding processes of today include?

2. What are the principles of gas welding?

3. What kinds of welding can be used for joining steels?

4. What does arc welding require?

Find in the text.

1. процесс сварки

2. имеющееся оборудование

3. сварочный электрод

4. плавкий материал

5. непрерывная подача электрического тока

6. электрическая дуга

7. источник электрического тока

Find 9 words and write them.

Flameedgesimultaneouslyfillerwirerodmeltjointcoated

Read in the text.

1. …to melt metal and create a weld.

2. …advantages over other welding methods.

3. …using heat from a gas flame.

Дата добавления: 2018-11-24; просмотров: 640; Мы поможем в написании вашей работы! |

Мы поможем в написании ваших работ!