Qualimetrical assessment of quality of production.

The scientific area uniting the quantitative methods of assessment of quality used for justification of the decisions made at product quality control and standardization is called a kvalimetriya. The main objectives of a kvalimetriya – to define the nomenclature of necessary indicators of quality of production and their optimum values and also to develop methods of quantitative assessment of quality, to create a technique of accounting of change of quality in time, to simulate gradation of quality. The qualimetrical analysis is considered in the most objective way by means of which it is possible to choose and estimate material. Nevertheless, at the same time it is necessary to consider such provisions as: for what conditions and for what purpose this assessment becomes. Besides it is necessary to consider such situation as quality which represents set of the properties of material located at the different levels. In addition it is necessary to consider that qualimetrical assessment of quality has dependence on quality indicators and also on the system of key indicators accepted for assessment which define quality of a standard. At last when carrying out such analysis it is necessary to consider estimates of properties which can define quality at any level. These estimates have unequal ponderability which has dependence on requirements which are imposed usually to the corresponding properties of level.

In qualimetrical assessment of quality of production distinguish concepts:

1. Properties of quality.

2. Quality indicators.

The qualitative or quantitative characteristic of any properties or conditions of production is called sign of production. At change of properties of products quality indicators change. Understand determination of numerical values of certain indicators of quality as quantitative assessment of quality of production. Such assessment is usually used for the choice of the most optimal variant, for planning, control, for studying as in dynamics the quality and also for carrying out certification of quality of finished goods is improved. Subject of the analysis is production which is exposed to the qualimetrical analysis. At the same time there is no dependence on their look, appointment and structure.

Property is called the characteristic of production which is shown during its application, in the course of his processing or in use.

Usually understand difficult property which is, in fact, set of esthetic and functional properties of a product as quality. The integrated quality is the most difficult property of production which is defined usually by set of profitability and quality of this production.

|

|

|

At qualimetrical estimates of quality of kefir are used the following methods: differential, expert.

The method of differential of level of quality based on comparison of single indicators of quality of the considered product sample with the same indicators of quality of a basic sample is called differential. This method is applied when it is necessary except assessment of level of quality of production in general, to carry out the analysis of level of its separate properties. As a result of application of this method define, will reach basic level of quality in general or not on what indicators it is reached on what isn't present and what indicators most strongly differ from basic and so on. Assessment of level of quality by a differential method consists in calculation of values of single relative indicators of quality, and in the simplest

case the following formulas are for this purpose used:

qi=Pіδ/(Pδ ) or qi=(Pδ )/Ріδ (1)

i = 1,2

whereРі- value of an indicator of quality

Ріδ -Basic value of the indicator

Among 2 dependents he chooses dependence on the level of development of technologies.

Differential method.

The method based that the product represents a set of individual indicators of quality on the basis of his basic indicator is called the differentiated method of assessment of his indicator of quality.

Certain indicators of quality of the estimated product can be compared to their

major importances as follows:

1. Relative values of all indicators it is more or are equal 1 where the technological level of the estimated product is higher or it is equal to the basic line:

;

;

2. Relative values of all indicators  , the technological level of the estimated product is lower than basic:

, the technological level of the estimated product is lower than basic:

;

;

3. A part of relative values of indicators are more or is equal, and other part less than 1. In this case for assessment of quality of a product it is necessary to use a complex method. For example: differential assessment (table 6)

|

|

|

Table 6 - Quality assessment with use of a differential method.

| Name of indicators | Xi-volume of indicators | Xi-volume of a controlled indicator | qi-relative value of an indicator |

| 1 | 2 | 3 | 4 |

| Mass fraction of fat, no more than a% | 1,0 | 0,90 | 1,1 |

| Mass fraction of solid, no more than a % | 12,0 | 11,0 | 1,09 |

| Mass fraction of vitamin C in 100 g of a product, not less |

20 |

21 |

0,95 |

| Conditional viscosity , с | 20,1 | 20 | 1,005 |

| Lactations , ºT | 90 | 85 | 1,05 |

| Temperature ° C, not less | 8,0 | 8,0 | 1,0 |

| Lead , no more | 0,12 | 0,1 | 1,2 |

| Cadmium , no more | 0,034 | 0,03 | 1,13 |

| Arsenic , no more | 0,053 | 0,052 | 1,01 |

| Mercury,no more | 0,0052 | 0,005 | 1,04 |

| Copper, no more | 1,01 | 1,0 | 1,01 |

| Zinc, no more | 5,02 | 5,0 | 1,004 |

q1 =1,0/0,90=1,1

q2= 12,0/11,0=1,09

q3= 20/21=0,95

q4= 20,1/20=1,005

q5=90/85=1,05

q6= 8,0/8,0=1,0

q7= 0,12/0,1=1,2

q8= 0,034/0,03=1,13

q9=0,053/0,052=1,01

q10= 0,0052/0,005=1,04

q11= 1,01/1,0=1,01

q12= 5,02/5,0=1,004

In the table the level of quality of a kefiric product by a differential method was estimated. According to the data provided in this table we see that the technological level is above basic level. Therefore,

Complex method of assessment of quality of production.

The complex method of assessment of level of quality provides use of the complex (generalized) quality indicator.

At this method the level of quality is defined by the relation of the generalized indicator of quality of the estimated production of Qots to the generalized indicator of quality of a basic sampleQбаз.

(2)

(2)

All complexity of complex assessment consists in objective finding of the generalized indicator.

There are various options of a method.

1. When it is possible to allocate the main indicator characterizing basic purpose of a product or product and to establish functional dependence of this main

|

|

|

indicator on other single indicators:

(3)

(3)

where n-число единичных показателей;

Pi-i-single indicator;

Yi-coefficient at single indicator.

The type of dependence can be defined by any of possible methods, including and expert.

For example, productivity of cars, a resource, specific prime cost, etc. can be the main indicator.

As generalized the integrated indicator of quality showing the size of useful effect of operation or the consumption of production falling on each ruble of total costs of her creation and operation or consumption can be used.

2. When it is impossible to construct functional dependence, proceeding from basic purpose of production, apply the weighed arithmetic-mean indicators. At the same time the generalized indicator is calculated on a formula:

(4)

(4)

where mi-coefficient of ponderability of i of an indicator.

At the same time the condition has to be met:

(5)

(5)

Ponderability coefficients mi are established by branch scientific research institutes for a certain period of time by an expert method by poll of a certain number of experts who, proceeding from product service conditions, appoint points of the importance of each parameter Pi. On the basis of mark assessment of the importance of parameters coefficients are defined mi.

Differential and complex methods of assessment of level of quality of production not always solve objectives. At assessment of the complex products having wide quality indicators by means of a differential method it is almost impossible to draw the generalizing conclusion, and use only of one complex method doesn't allow to consider objectively all significant properties of the estimated production.

In these cases assessment of level of quality is made by the mixed method using single and complex indicators of quality. At this method single indicators of quality unite in groups (for example, appointment indicators, ergonomic, esthetic) and for each group define a complex indicator. At the same time separate, most important indicators don't unite in groups, and use as single. By means of the received set of complex and single indicators estimate level of quality of production by a differential method.

|

|

|

Expert method of assessment of quality of production.

For determination of weight coefficient by expert methods the commission of experts consisting of highly qualified specialists is created. The commission of experts accepts the weighing factor based on a method. However it is necessary to take concrete measures for decrease in suitability of an expert method for obtaining exact results. For this purpose there are several types of questionnaires. Work on examination is carried out as follows. Each expert, independently of each other, gives value or value of criterion of quality which he considers corresponding to weight coefficient. Then each expert has to prove the values or estimates.

и

и  ;

;  (5)

(5)

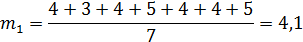

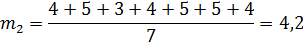

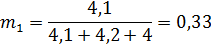

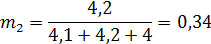

For example: it is necessary to define weight coefficient of quality of a kefiric product. Experts determine calorie weight by three indicators:

m1-indicator of fat content of kefir;

m2-indicator of acidity of kefir;

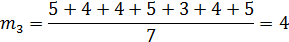

m3-indicator of appearance of kefir.

Calculation of kefir for expert assessment is given in table 7.

Table7- Calculation of kefir for expert assessment

| Expert | Appearance indicator, point | ||

| m1-fat content indicator | m2-acidity indicator | m3-appearance indicator | |

| The first | 4 | 4 | 5 |

| The second | 3 | 5 | 4 |

| The third | 4 | 3 | 4 |

| The forth | 5 | 4 | 5 |

| The fifth | 4 | 5 | 3 |

| The sixth | 4 | 5 | 4 |

| The seventh | 5 | 4 | 5 |

| Avarage value | 4,1 | 4,2 | 4 |

(6)

(6)

(7)

(7)

Дата добавления: 2018-06-27; просмотров: 585; Мы поможем в написании вашей работы! |

Мы поможем в написании ваших работ!