Explain how to determine the test section length of hydrostatic testing.

Multiple Choices /True or False

1 Pipeline maintenance work can be divided according to their size and nature: (a) Routine (the repair); Planning (overhaul); Accidental (repair) (b) Routine (the repair); Accidental (repair).

2 Emergency telephone number in Kazakhstan: fire (101), medical (103), police (102) (a) 101 (b) 102 (c) 103

3 Risk management can be thought of as a method to improve ( ) (a) hazard; (b) quality; (c) risk.

4 The failure rate of a pipeline system changes over time (a) increases; (b) decreases; (c) changes at the bathtub shape .

5 (a) ASME B31.4 , ASME B31.8 , and API 1104 (b) API1104 (c) ASME B31.4; B31.8 ( ) give a detailed description of welding pipelines.

6 If air exists in the line under pressure, the field value ΔV/ΔP will be (a) larger (b) same (c) smaller than the theoretical value.

7 No pipeline operator may operate a pipeline unless it has been pressure tested in accordance with CFR Title 49 part (195 (for Hazardous Liquid) and 192 (for Gas Pipelines )) without leakage.

8 The test pressure conducted for a minimum of ( 4h ) period, at a pressure at least ( 125 )% of MAOP.

9 Distribution piping is limited to 20% SMYS (a) true; (b) false.

10 The methodology of the scientific methods involves (hypothesis) generation and testing. It requires both inductive and (deductive) reasoning.

11 Full names of IPD (inadequate penetration due to high-low) and MIC (microbiologically induced corrosion).

12 Full names of MAOP (Maximum allowable operating pressure) and SMYS (Specified Minimum Yield Strength).

13 Full names of PI ( pressure indicator ) and ECDA (external corrosion direct assessment ).

Answer Questions

List internal corrosion causes and methods of corrosion control.

The causes of internal corrosion are many and can be generally divided into:

1. The chemical composition of the stream

2. The physical factors of the stream

3. The physical factors of the structure

All methods of corrosion control fall into one of the following categories:

1. Coatings

2. Cathodic protection (anodic protection)

3. Filming inhibitors

4. Alteration of the environment

5. Material selection

6. Alteration of the structure

7. Repair or replace

List leak detection methods. List two types of pigs and examples.

Prevention methods include the following:

|

|

|

● Pressure regulation

● Cathodic protection

● Corrosion coupons

● Pipeline markers

● Smart pigging

● Pipeline security

● In-line valves

● Patrolling

Two types of pigs: Utility pigs, Poly pigs, Smart pigs: MFL and UT

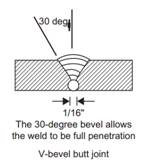

List three welding and two NDT testing methods. What are the benefits of using higher X-grade pipe and advantages of V-bevel joint?

three welding :Automatic; Semiautomatic; SMAW (Shielded metal arc welding)

two NDT :High frequency welded (HFW); Nondestructive testing (NDT) AUT X-ray (main);

USING HIGHER X-GRADE PIPE

To reduce pipeline cost at construction, both natural gas pipeline and liquid pipeline companies want to reduce the amount of tonnage used in their pipeline design, because pipe is sold by the pound. Using large diameter, higherstrength/thinner wall pipes can amount to substantial saving in construction costs. The companies not only save money by buying thinner pipes but also save because they use less filler metal (welding rod) to weld the thinner wall pipe and with less welding time needed. They will also enjoy a significant saving in shipping cost because of lower tonnage. Since higher-strength pipe will allow shipping gas and liquid products at higher pipeline pressures, the companies will be transporting more cubic feet of gas per hour or more barrels of liquid products per hour. The result will mean better pipeline efficiency and profit for the company.

advantages of V-bevel joint:good penetration; good mechanical properties, better connection

Explain how to determine the test section length of hydrostatic testing.

The procedure is follow as:

1. Select a test pressure range for the entire pipeline. The minimum pressure at the high point of the section should be 90% SMYS. The highest pressure of the section will be at the low point.

2. Plot the pipeline elevation profile

3. Evaluate the high and low pressure (psig) for the pipe to be tested

4. Starting with the low-point elevation, calculate the test section elevation at the high point. Using the Bernoulli energy equation: P1 × 2.308 + Z1 = P2 × 2.308 + Z2 and solving for Z2 elevation.

|

|

|

5. The test section length and location of test section end can be determined graphically by the intersection of the high-point elevation Z2 and the plotted pipeline elevation profile.

Дата добавления: 2018-05-12; просмотров: 283; Мы поможем в написании вашей работы! |

Мы поможем в написании ваших работ!